Innovations in Maintenance of Way: Enhancing Rail Infrastructure

Written on

Chapter 1: Introduction to Rail Maintenance

Have you ever considered the complexities involved in keeping trains operational? Imagine a world where locomotives could no longer transport goods and passengers. For many, especially those living near railroads, the absence of trains might be an unthinkable scenario. In this article series, we will delve into the essentials of railway maintenance, focusing on the critical role of ballast and the equipment used to maintain a solid rail bed free from defects.

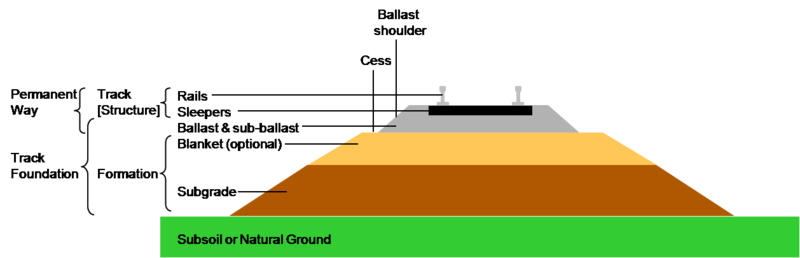

The image below illustrates the various components that make up a railroad track, highlighting the meticulous planning and expertise required in its construction.

Chapter 1.1: Understanding Maintenance of Way

Maintenance of way, commonly abbreviated as MOW, also referred to as Permanent Way Maintenance, encompasses the upkeep, construction, and enhancement of the rail infrastructure, which includes tracks, ballast, grades, and surrounding elements like signs and signals.

This series will explore ballast and the machinery utilized by railroads for its cleaning and replacement. Let's dive into the specifics.

Section 1.1.1: What is Ballast?

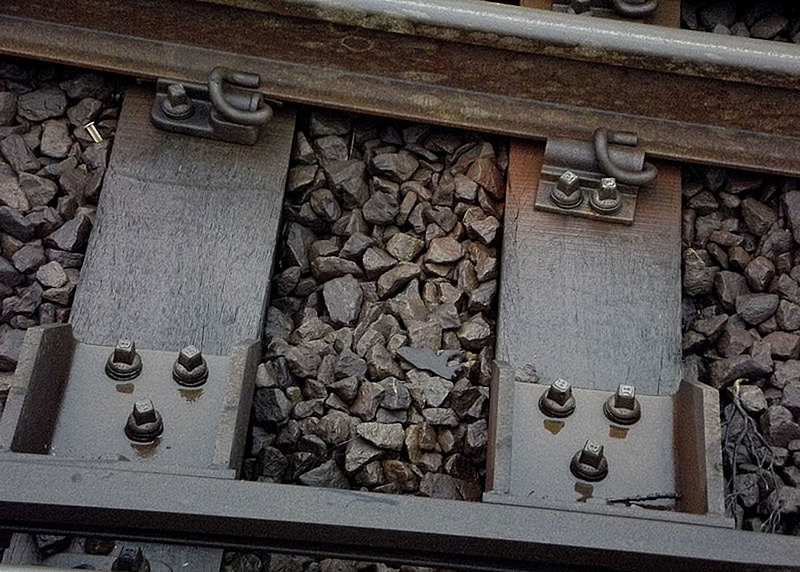

Ballast is the material that forms the foundation upon which railroad ties are laid. This rock is strategically placed between, beneath, and around the ties to support the weight of the ties, rails, and trains while facilitating proper drainage. Additionally, it prevents vegetation growth that could jeopardize the rail system's integrity.

Section 1.2: The Importance of Ballast Thickness

Ballast thickness varies based on tie size and spacing, line traffic, and other considerations. A minimum thickness of six inches is standard, while high-speed railways may require up to twenty inches. Insufficient ballast depth can lead to soil compression beneath the tracks, causing instability and potential derailments.

Chapter 2: Ballast Management Techniques

This video showcases the New Amtrak Maintenance Of Way Train at ECRR, focusing on the EMD GP38-3 and 41ft ballast hoppers, demonstrating advanced techniques for maintaining rail infrastructure.

Chapter 2.1: Laying and Maintaining Ballast

Track ballast is often laid atop a layer of sub-ballast, which consists of small crushed stones that help support the top ballast and prevent water ingress. It's crucial for the ballast to cover the ties effectively and create a robust shoulder to minimize lateral movement.

For safety, railroads must maintain tight control over track alignment to prevent derailments. The ballast stones should be irregularly shaped with sharp edges to promote interlocking.

Chapter 2.2: Ballast Removal and Replacement Techniques

Railroads can sometimes clean ballast without removal or raising the tracks; however, this is only feasible a limited number of times. When fouled ballast is present, cleaning it may not be the best approach.

To replace ballast, railroads use the "dump and jack" method, dropping new ballast onto the track, raising the entire structure, and tamping it down. There are also advanced techniques that involve using an undercutter to remove ballast without lifting the track.

The second video highlights the New Amtrak Maintenance Of Way Train at ECRR, focusing on Micro Trains Cement Tie Load Cars. This showcases innovative methods employed in ballast management.

Chapter 3: Ensuring Safety Through Regular Inspections

Frequent inspections of ballast along the railroad shoulder are vital for stability, especially after maintenance activities. If the ballast becomes uneven, it is essential to pack additional ballast beneath the sunken ties to restore proper alignment.

Chapter 4: Conclusion and Future Innovations

In conclusion, our exploration of the maintenance of way has provided insights into the critical role of ballast in ensuring safe and efficient rail operations. In the next article, we will examine new technologies and methods being introduced by manufacturers that benefit the railroads, enhancing safety and efficiency in rail maintenance.